TECH

Acavallo is a mashup of design ideas, some practical, some completely goofy. The goofiness is important! the practical more so!

THE PRACTICAL

It is a gooseneck trailer, which is how it gets around. The hitch is under the stage, and the piece travels backwards down the road. There are two trailer axles on leaf springs, and one pickup truck axle on airbags, to take the load. It weighs 13,000 lbs, heavy but not that heavy, it is 101" wide and 13' tall, has lights and reflective tape and a license plate and tows like buttah.

ready to tow back home.

three axles - two trailer, one drive

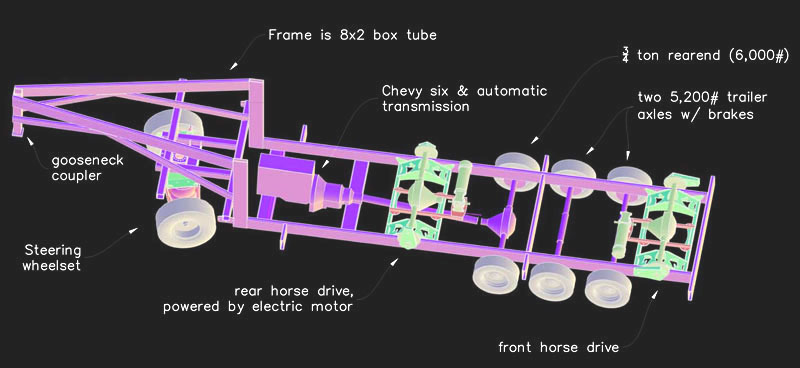

here's how things are laid out in the trailer core. There are another set of steering wheels out front, suspended by the side trusses.

It transforms quickly - the sides fold down, braces get pinned in, and the masts step up into place. So it's comparatively easy to set up. Then you can add speakers, awnings, sound, ropes and the gangplank:

It uses conventional automotive powertrain components to motivate - so it's sturdy, cheap, easy to fix. Nothing fancy -no big batteries, nor hydraulics. I love both those things but enough already. I wanted to go places, and it takes the almighty Internal Combustion Power to do that. And the easiest/cheapest way to get it to the ground is through an automatic transmission via an auto axle. In this case a Chevy 250 six, a 3 spd automatic, and a Dodge 1500 rearend. The drivetrain is laid out backwards, so that you shift into the old reverse to drive the ship forward. The driveline gets disconnected for towing.

Chevy 250 six and 3 spd auto.

the horse drives use more automotive axles - they've been welded to eliminate the differential action, so they stay balanced. They're set so that as one horse goes up, its opposite goes down, and the load balances. The steel horses weigh the same as a person, about 160 lbs, and will support at least four. Around and around they go, as long as the generator doesn't run out of gas - they're driven by electric motors. I happened to have a bunch of surplus equipment from my career in theatrical automation, which shows up throughout the piece: bearings, motors, drives, caster wheels, pulleys and many, many bolts. Plus the design techniques which make it all possible - tubing and tabs.

muscling a horse drive assembly - all 500# of rusty goodness

as a schematic. The horses are driven at the bottom, the cranks go round and round. The wings at the top flap up and down and keep the horse centered. Ball joints are used at the pivots, at the top, three per wing. Two at the catwalk and a bigger one at the horsepole. The bearings at the bottom are big 2-bolt flange units, on 2" shaft stubs. They're self-aligning so the horse has a little wiggle. But it keeps it all loose, and nothing binds. Watch your feet up at the catwalk, though, those flappers are shin crushers for sure.

Watch your feet!!

Anyway. If you look around and especially underneat the car, you can see it all laid out in front of you. Nothing is hidden, really. The open truss sides are great for that - you can see it all.

The ridiculous:

..

the big airbagged ag wheels and tires that both steer and support the live load of the participants. These bolt on/off for trouping. There are two at the front, two at the back, and two at the sides.

airbags push down on an a-arm with a big ag hub welded to it. It pivots on two big rod ends.

We had as many as 80 people onboard, or the entire piece weight, doubled. That weight is carried by the big 18 ply agricultural tires, on ag hubs pushed down by big round airbags. They're all on these goofy swingarms, which use big rodend bearings bolted to weldments of waterjet cut 1/4" steel plate to articulate. And it is a terrible suspension design- the bottom of the wheel has to scrub back and forth on the ground as the arm bounces up and down but hey. What's important is that it does bounce up and down, it is lively, bumpin up and down to the beat from stem to stern. The airbags in the back are especially working, carrying all the weight of the stage, the band, the motor, the generator, all that pressing down into the ground through those bags. They also steer, those wheels. more about that later.

If the air gets low (like a leaky hose overnight) the piece will do a wheelie by morning, all the air pressure draining away and those big bags collapsing limp and the back tires slip out sideways like the hind legs of a plump chihuaha belly floppin and the rear drops, lifts the front and wheelie. The front wheels come off the ground. Which is a good party trick. It is a slllooow acting party trick, though, it doesn't really do anything fast, the air system.

air pressure is low, see how the back wheels start to fold up? time to kick on the generator

..

The air is supplied by an oilless compressor, oilless so we could turn it sideways and hide it under the deck. It runs off the main generator. The air goes down when everybody gets bouncing, each bounce poppin a little back through the regulator. So it runs every hour or so. Hard to tell, unless the horses are all heavily loaded, because it trips the breaker on the generator and then you can tell, but otherwise, who's gonna notice a little more racket?

The air system is actually pretty simple, the compressor feeds a manifold, with a pressure regulator for each set of airbags, and a valve to dump them for maintenance. Everything is connected with rubber hose, with the classic hose-barb and hoseclamp at each fitting, and shop-style quick connect couplings where things have to break for transit or maintenance.

It just needs to be run every now and then to keep the pressure up.

..

It steers by pivoting the front and rear ag wheels. They are in sets of two, and pivot on fancy Kaydon crane Bearings, recycled out of theatrical equipment. I paid top dollar for these back in the day. They make it rock solid!

When you turn the steering wheel, it turns the input shaft of a dual-output gear reducer, which turns two number 50 chain sprockets, which pull wire rope cables, which pull the wheels to and fro. The sprockets are different sizes - the back wheels turn more, the front less, to keep the center of rotation lined up with the middlemost axle on a turn. Exciting stuff.

Steerin to the left... pullin on that smooth arc past the lampost out of frame to the right

It all works great, except that the wheelsets (the back ones especially, which are tremendously loaded) can oscillate or get a waddle going. It doesn't seem to care too much, the piece rolls right along, but it does bend the pulleys over and while it is entertaining I feel like it needs some damping. And possibly some caster, or maybe caster first and damping second. By 'caster' I mean an offset in plan view between the centerline of the two wheels and the pivot center on the bearing. So that the wheels will naturally return to straight, like on a car. I can't remember why I didn't design caster into them, it was so long ago. It is a design mistake! The cables get to wiggling and don't want to stop. So upgrades are imminent.

turn the wheel, the sprockets rotate, and pull aircraft cables that lead to the wheels fore and aft

the controls are whimsical as well:

That's the shifter with the feathers in it, set up to ratchet into Park (toward the driver), then Fwd, then Neutral, and all the way to the end for Reverse. The shifter lever that goes down from it is over six feet long. I've got my hand on the throttle, which is an old lever from a logging machine. It's wonderful, you pull it towards you and there's a vroom from beneath the floor and a surge of acceleration. It's connected via a throttle cable kit from summit. Note also in this picture that the steering got regeared - there's a 2:1 speedup into the reducer to get it to turn faster. It's still slow but that's kinda fun. The crowbar in the foreground is for the juice brakes, which are not working right now, but they look cool. There's an ebrake handle that pulls the cables to the brake drums and works waay better anyway - it's much more controllable and a lot less effort. It's all the same brake shoes, so we've yet to fix the hydraulic lines. Anyway. The brake handle is pretty cool - it's out of my dad's collection of old chevy parts. It's got a super cool linkage inside itself to do the ratcheting and pull. Ask me to show it to you sometime, I love it. The other important feature is the necker knob on the steering wheel - it's a real drag without it. It takes a lot of spinning to get a turn going. It's good times!

The completely impractical:

driver sightlines.It really needs some video cameras, so it'll get that next year. It was intensely satisfying to drive it like this though, to summon every bit of my attention and 3D mental modeling to navigating through the seas of black rock without a collision. At the end of the week, I could pass within inches of a lamppost and not even flinch. I had it. Driving, for me, really involves extending your consciousness to the vehicle, it's tires are your tires, its edges yours. This is so much to absorb! It's the best. I go to Burning Man just to drive free, really. To drive with whimsy. |